Prototype Railroads Try to Avoid Grades

Model Railroaders Add Track Grades Purposely

To Add Interest or Cross Over Other Trackage

Here’s How to Add Grades to Your Model Railroad Layout

Whenever railroad track – prototypical or model – is not level, it’s considered to be on a “grade.”

You may have noticed when traveling on a highway in hilly country that nearby railroad tracks do not follow the terrain as closely as the highway does. While the road may go up and down repeatedly, the railroad track instead follows a much more gentle up and down path, with earthen fills or bridges over the lowest elevations and cuts through the highest points in the terrain. This is because a railroad locomotive, pulling a much heavier load than an automobile or semi-truck, depends on the friction of its steel wheels on steel rails for its pulling power. It simply cannot climb as steep a hill as a lighter road vehicle traveling on rubber tires.

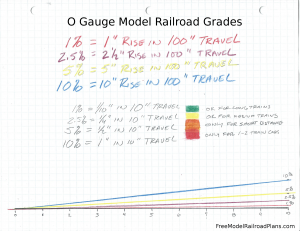

Railroad grades are measured in the percentage of rise over distance traveled; a rise in elevation of one foot per 100 feet traveled would be a 1% grade (see Figure 1). Among prototype railroads, this would be a steep grade for all but those railroads traversing tall mountain regions. As an example of what a challenge to railroad operations a grade introduces, to keep its grades at no more than 0.5% on its route along the upper Potomac River in the hill country of western Maryland, the Western Maryland Railway went to the expense of building miles of retaining wall, six multi-span bridges, two creek crossings, a number of concrete culverts, and three tunnels over a distance of less than 35 miles. Even this grade would have required the use of “helper” locomotives added to trains heavy coal trains along this route.

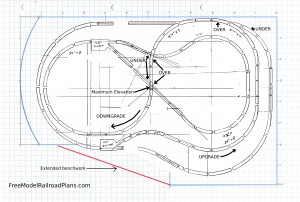

Where prototype railroads use grades only when they have to overcome challenging terrain – and as the Western Maryland Railway examples shows, they will resort to expensive remedies to avoid or minimize grades even then – model railroaders often introduce grades simply to add interest to their layouts. But probably the most common reason for a grade on a model railroad layout is that, due to limited space, our tracks must cross over one another as we bend them to fit the space available. Our O Gauge Model Railroad Project is a combination of the two, where we added an over/under figure 8 design to create a point of interest for our 54” diameter inner track loop (see Figure 2).

Going back to Figure 1 it’s good to note that model railroaders can use much steeper grades than prototypical railroads. A 1% grade on most model railroads, because our trains tend to be much shorter and our cars much lighter proportionally, is not a steep grade. And an O gauge model railroad will often utilize even steeper grades than even most “scale” model railroads – as much as 5% on the mainline (confused about the difference between “scale” and “gauge”? See our Scale vs. Gauge page – however in this use, I make the distinction between model railroaders looking to reproduce very-close-to-scale layouts as opposed to an O or S Gauge “toy” train layout, even a realistic one like our O Gauge Model Railroad Project). Most “scale” model railroad layouts would only use a 5% or higher grade as a deliberate challenge to operations to mimic mountain railroading.

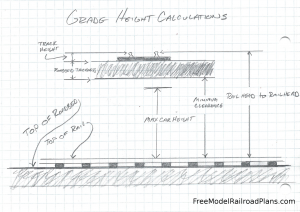

In the case of one track crossing another, no matter what scale you are modeling, there are several measurements you must make to calculate the grade you have to use to achieve your purpose (see Figure 3). The first thing to consider is your maximum car height. This is easily measured as shown in Figure 4a. However, make sure if it’s a mainline crossing that you measure the height of your tallest rolling stock (see Figure 4b).

But, just as there are areas of older prototype railroad trackage where the limited clearance doesn’t allow double-stack cars, if you are crossing a meandering siding that would have no reason to accommodate an over-height car, creating a crossing that WON’T accommodate such rolling stock can add an interesting challenge to operators of your model railroad layout.

Adding a safety factor to your maximum car height gives you your minimum clearance needed for one train to pass beneath another. On our O Gauge Project Layout I gave myself a comfortable 6 3/4” from the top of the rails to to bottom of the upper roadbed. This is about an 8-inch clearance from “ground level” of our plywood base to the bottom of upper roadbed. You could get away with as little as 1/4” added to max car height in O Gauge; In smaller scales you could allow less.

But, the height the train must climb to give you the minimum clearance is actually railhead to railhead. This distance includes not only your minimum clearance, but the thickness of your roadbed and the height of the track on the upper level. Our roadbed is 3/4” foam bonded to a 1/8” plywood base, and O-27 track is nearly 1/2” high, so our railhead to railhead height is right about 9 3/8”.

How far do we have to travel to reach a height of 9 3/8” at a 5% grade? To find out, we need to divide the decimal equivalent of our desired height by the decimal equivalent our grade percentage:

9.375/.05=187.5

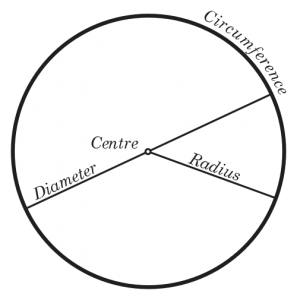

So, we need a track run of 187.5” to reach our desired height. Now we are faced with the problem of measuring this distance when we have curved track. If you have the pieces, you can assemble them and then run a string down the center rail, and then measure the string (be careful not to stretch the string when measuring it). Or, you can resort to geometry. We need to know the distance a train travels when going around a circle. This distance is the circumference of the circle (see Figure 5).

We know we have 54” curves on this circle. With O Gauge track, the 54” measures the diameter of the circle those tracks would make (in other scales, size of the curve indicates the radius of the circle those tracks would make). The formula to calculate the circumference of a circle is:

C=πd (Circumference = Pi x diameter)

Pi is the constant ratio of a circle’s circumference to its diameter. All you need to know for this calculation is its value is about 3.14. So our formula to calculate the distance a train will travel around a 54” diameter circle is:

3.14 x 54 = 169.56

So, our train travels about 169 1/2” around a complete 54” diameter circle of track. Since we don’t have a complete circle, it helps us to know that it takes 16 pieces of 54” diameter track to complete a circle. So, if we divide our total circumference by 16, we realize each piece of track is slightly longer than 10 1/2” (10.6”). Straight O-27 track pieces are just shy of 9” (8 7/8” or 8.875”) and half straight tracks about 4 1/2” (4.4375”). If you count the track pieces used for the 54” loop of track from the switch at the bottom left of the drawing where it begins, you’ll see we have 15 curved tracks (one is a 42” curve, but let’s count it as a 54”), five full-length straight tracks and two half-length straight tracks before the loop must reach our minimum clearance to cross over the first lower track. So:

- 15 pieces of curved track at 10.6” each = 159” travel;

- 5 full-length straight track at 8.875” each = 44.375”

- 2 half-length straight track at 4.4375” each = 8.875”

Adding these figures together, is shows we have a total track run of 212.25” before our first crossover, more than enough to reach our minimum height at a 5% grade. Given this extra distance we could create a transitional grade of 2.5% on the first and last 10” of our track to ease the change from level to grade track.

Next we need to create risers to put under the roadbed of the grade track to lift it to its intended height (see Figure 6). As these risers fit between “ground level” and the bottom of the roadbed of our grade track; at full height, they will be our “minimum clearance height” of 8”, which we discussed earlier. With our foam/plywood roadbed, risers every 10” are sufficient to support the track. Remember, our first and last 10” of track rise at only 2.5% as a transition from level to grade track. So, to calculate the height of the first riser, we start at a height of 0 “ground level” for the track and add the height the track rises at 10 inches (refer back to Figure 1: a 2.5% grade lifts the track .25” for every 10 inches; a 5% grade lifts it .5” every 10 inches). Our first riser lifts the track just 2.5% so at 10 inches, the riser is .25” high. To calculate the height of our second riser, we need to start with the height of our first riser, and add to that. The second riser lifts the track 5%, so its height is .75” (we begin at a height of .25” and add .5” (.05 x 10” = .5”). Below is a table showing the height of each riser needed to reach the height we calculated to cross over another track.

| RISER CALCULATION TABLE | ||

| GRADE | DISTANCE | HEIGHT |

| 0.00% | 0 | 0 |

| 2.50% | 10 | 0.25 |

| 5.00% | 20 | 0.75 |

| 5.00% | 30 | 1.25 |

| 5.00% | 40 | 1.75 |

| 5.00% | 50 | 2.25 |

| 5.00% | 60 | 2.75 |

| 5.00% | 70 | 3.25 |

| 5.00% | 80 | 3.75 |

| 5.00% | 90 | 4.25 |

| 5.00% | 100 | 4.75 |

| 5.00% | 110 | 5.25 |

| 5.00% | 120 | 5.75 |

| 5.00% | 130 | 6.25 |

| 5.00% | 140 | 6.75 |

| 5.00% | 150 | 7.25 |

| 5.00% | 160 | 7.75 |

| 2.50% | 170 | 8 |

Remember to cut two of each riser, since the track must descend after it crosses over the lower track, and as many of the tallest ones needed to support the track as it travels at maximum rise. If you have an adjustable miter saw, you can cut the top of each riser at the angle of the grade at that point, either 2.5% or 5%, for a better fit, or you can just use shims between the riser and roadbed on the high side.

Figure 7 shows the risers placed under the roadbed of the 54” loop of our O Gauge Project Layout, raising the track to the point it crosses the lower tracks of the 42” return loop.

Grades create an area of interest on a model railroad layout and add to operational interest. With the formulas provided here you have a jumping off point to add much more interest to your model railroad layout.

Please Support FreeModelRailroadPlans.com

FreeModelRailroadPlans.com is entirely user supported. If you find something of value here, please “pay it forward” and help us keep the site operating by a secure donation through PayPal (PayPal account is not required), or by shopping with our advertisers.

Thank you for your support!

Very good teaching . Thank u so much

A lot of very good information presented clearly and easy to understand.

Thanks,

John

You can also improve height/grade substantially by lowering the bottom track of the crossing below table grade.