Return to the Sacramento Shops main page

Car Shop No. 3, which began as an extension of the Planing Mill, saw drastic changes in function throughout its existence. In the early years, it primarily was the site of construction, refurbishing, and maintaining passenger cars. New construction ended after the Depression, but passenger cars continued to be refurbished there into the 1950s. [1]

With the proximity of Car Shop No. 3 to the Erecting/Machine Shop, as the railroad dieselized its motive power in the 1940s – 1950s, more and more space in Car Shop No.3 was set aside for small to medium sized diesel locomotive component repair and rebuilding.

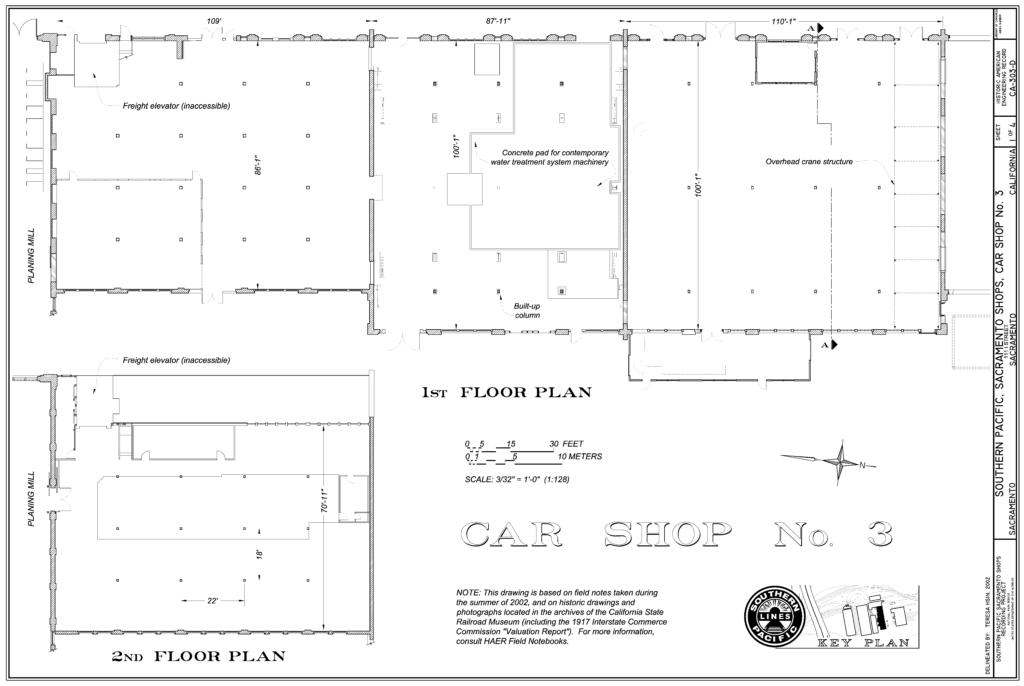

The original 1869 building was 45 by 90 foot “L” attached to the Planing Mill at its southeast corner. At this point it only contained two bays, and its east façade aligned with that the Planing Mill. Per usual for buildings at Sacramento Shops, the southern wall was wood, to allow for easy expansion.

Originally the building housed the Upholstery Shop on the first floor, with offices on the second. Under Superintendent Ben Welsh, the Upholstery Shop made “doors, windows, and upholstery from California material … at a cost quite as low as than of the same articles imported.” The cost of importing materials from the East was the impetus for much of the Sacramento Shops’ self-sufficiency in making its own parts and even constructing locomotives and rolling stock from the ground up.

The Central Pacific (progenitor of the Southern Pacific) found almost immediately after it finished the building that its growing car fleet necessitated a shop of its own, and in 1872, the company built an 11-bay 300-foot long extension to the original building. The addition appeared identical from the outside, other than a difference in roof color that can be seen in historic photos. On the inside, however, the new section was a single story, unlike the original’s two stories.

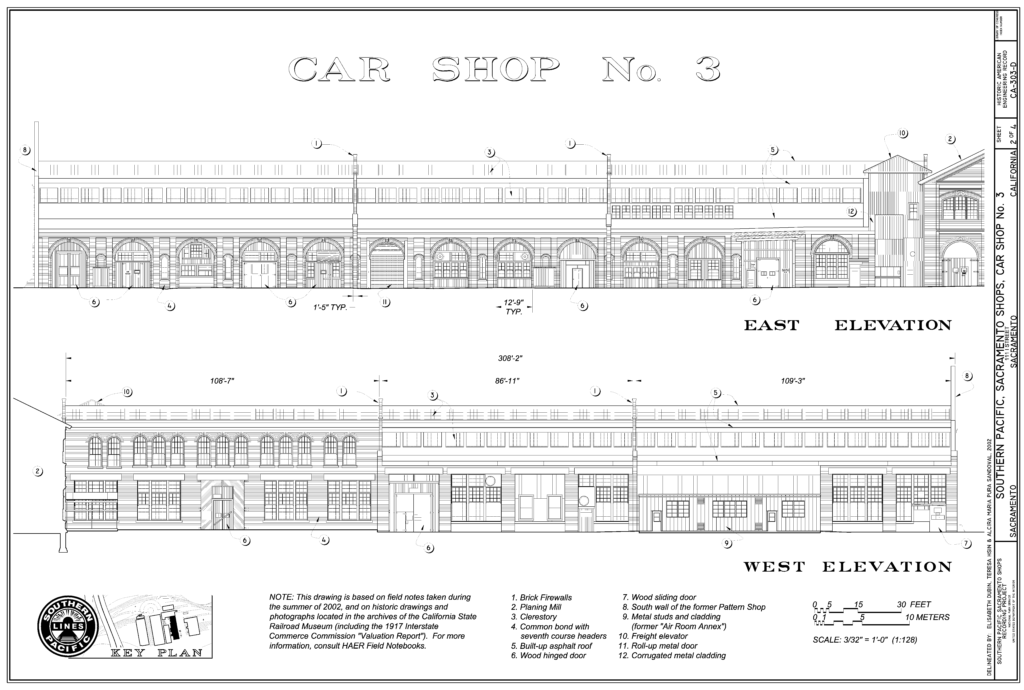

The new section also had a foundation of brick and redwood grillage, where the original had a rubble and brick pier foundation. The building housed 12-foot wide bays on 22 foot centers. The façades matched those of the Planing Mill, with double-pilasters with rectangular sashes between on one side, and round-arched windows on the opposite side.

This space was used for the final stages of car fabrication, completing an average of four per week. Painting was also done in the space, with an average of eight cars in for painting at a time. However, as soon as the space was opened, it was realized that car construction and painting would need more space. A new building was built east of Car Shop No.3, with a horse-drawn transfer table separating the two. Painting operations were moved to this building, allowing the original to concentrate on construction, with two bays housing planers and drills, five bays were used for constructing passenger cars, and three bays were reserved for repairing existing passenger cars.

Car Shop No. 3 was extended again in the early 1890s, with a 90 by 96 foot addition designated as the Pattern Shop. The double-pilaster design continued on the façade, but the new section was two story, as opposed to the single story of the central part of Car Shop No. 3, so the addition appeared to be a separate building. The Pattern Shop, however, occupied the second floor only, and the four bays on the ground floor were used for car work.

Around the turn of the century an electrically-powered transfer table replaced the horse-drawn table, and an elevator was installed in the northeast corner of the shop where there were two floors. The elevator, situated on the wall joining Car Shop No. 3 and the Planing Mill also offered access to the second floor of the Planing Mill.

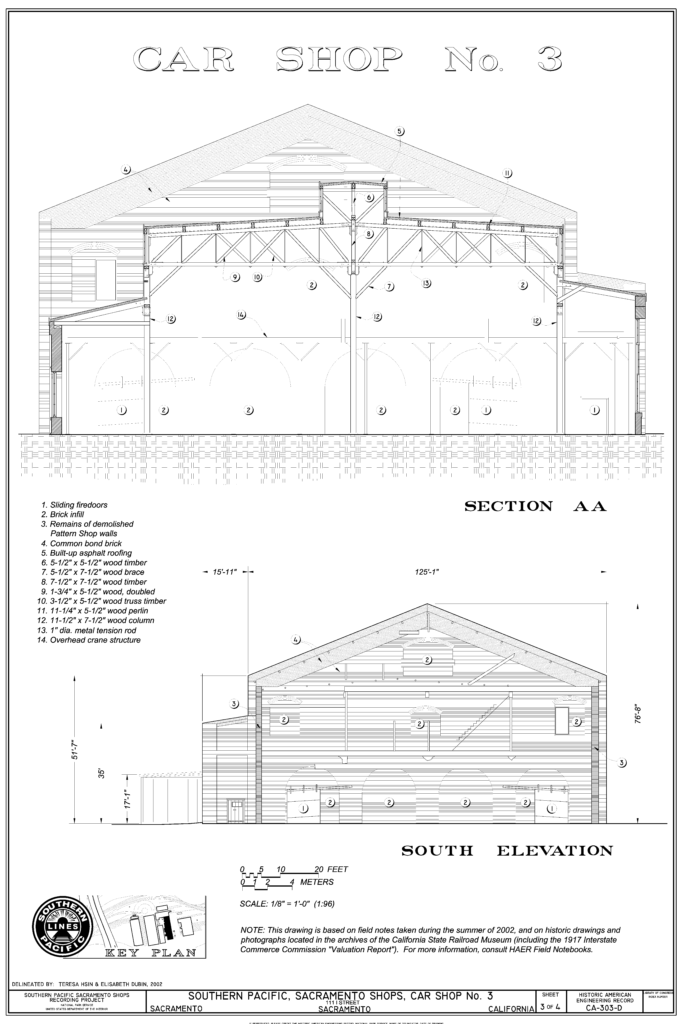

In a fire in 1916, all but five northern bays of Car Shop No. 3 were destroyed. The southern wall of the car shop kept the fire from spreading any further into the Pattern Shop. The brick eastern wall survived, and was retained for the reconstruction. Noting that the brick walls stopped the fire from spreading, two brick firewalls with fireproof doors were added during reconstruction, turning the open-bay building into separate sections.

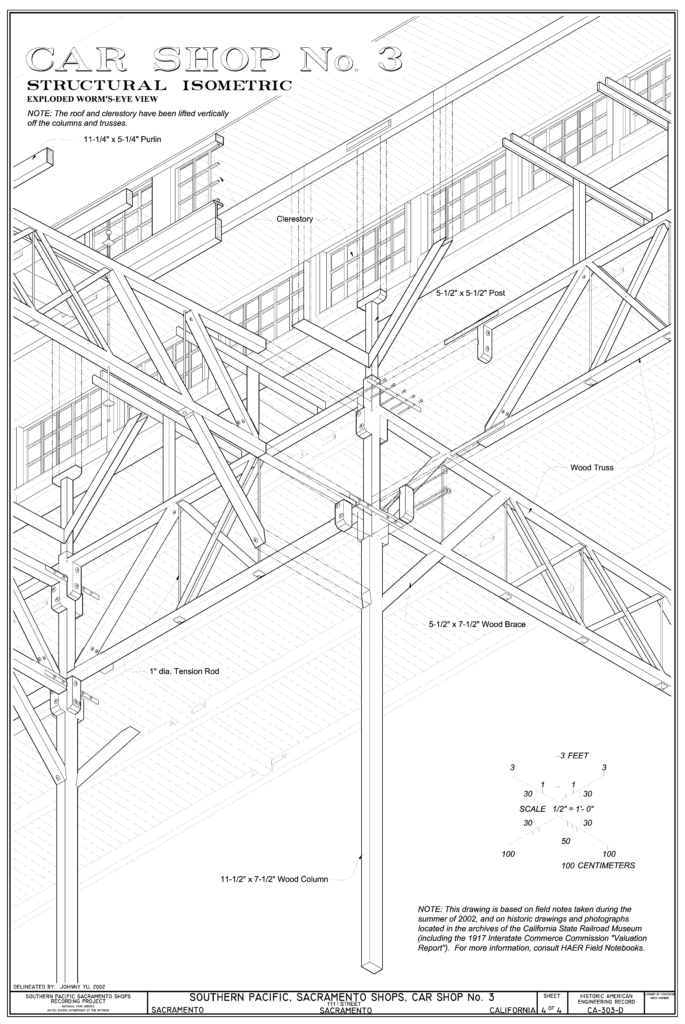

In rebuilding, the rear wall of the middle bays was moved to the west by about 10 feet to accommodate longer cars. The firewalls divided the shop into sections of four or five bays. Window area was increased with a double clerestory roof. The northern five bays, spared by the fire, were rebuilt to match the new width of center section, and the second floor that was above the northernmost two bays was expanded to cover all five northern bays.

As passenger car construction turned from wood to steel, although Sacramento Shops constructed some of the early prototypes, the railroad ended up turning to Pullman and American Car and Foundry for most new steel cars. The reconstruction after the 1916 fire gave the shop the height and width needed for steel passenger car repair.

Passenger car repair volume began to decrease in the 1930s, but with the arrival of the first diesel switchers in 1939, the excess space was quickly taken up by diesel locomotive maintenance, and passenger car repair moved entirely to the Paint Shop building. By 1946, the wooden floors of the second floor over the northernmost section of the building – now the diesel locomotive Electrical Shop – had become “rough, worn, and splintered.” They were coated with a fireproof combination of “dry cement and aggregate with an emulsion binder reinforced with expanded metal,” which lasted for the rest of the building’s service life.

In 1949 a new automatic electro-hydraulic unit built by the San Francisco Elevator Company replaced the old, obsolete elevator on the wall between the Planing Mill and Car Shop No. 3. An outside shaft protruding from the building, clad in corrugated iron, accommodated the new elevator.

In 1950, the Electrical Shop expanded to the section of building to its south, displacing the Locomotive Pipe Shop into a new location. The new space allowed it to expand from locomotive traction motor service to servicing the main generators of diesel locomotives. A crane was moved from the Locomotive Machine Shop to the Electrical Shop to assist in servicing the large electrical equipment. This required the replacement of three wood columns with steel columns and girders to support the crane and the wood truss above it.

The diesel operations in the building meant that entire cars no longer had to enter the shop, so most of the large doors were closed in with windows or smaller doors. By the time the shop closed in 1999, the building was a mixture of materials and designs from two centuries. The eastern wall was the original 1872 masonry that survived the 1916 fire. The sections created by the addition of fire walls had each been modified to create entirely different spaces in an area that was once 15 identical bays. Altered support structure, windows, and extensions demonstrate how changing needs affected the building’s architecture.

This recording project was completed by the Historic American Engineering Record; the Erecting and Machine Shop Survey HAER CA-303. This project, completed in 2001-2002 was prepared by historians Carolyn Dougherty, LeeAnn Bishop Lands, J. Lawrence Lee, and Camille Vicenti. Plans were delineated by Joshua May, Pete Brooks, Theresa English, Teresa Hsin, Elisabeth Dubin, Alcira Maria Pura Sandoval, Johnny Yu, and Elena Vuncheva. Photos were made by Jet Lowe.

[1] Historic American Engineering Record Survey HAER CA-303 Written Historical and Descriptive Data pp. 85-94 https://tile.loc.gov/storage-services/master/pnp/habshaer/ca/ca3100/ca3107/data/ca3107data.pdf accessed 06/01/2021