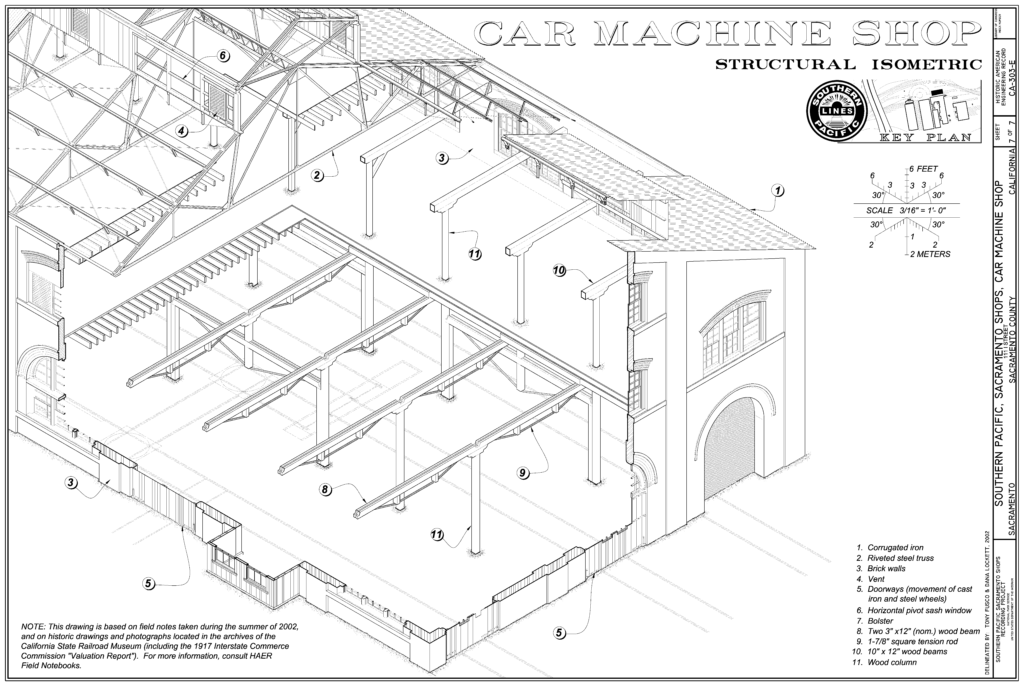

The Southern Pacific Railroad Sacramento Shops were the largest and most comprehensive railroad heavy repair facilities in the Western United States. The unusually self-sufficient Sacramento Shops repaired locomotives and cars throughout its life and built new ones as late as 1937. These drawings and photos are of the car machine shop. [1]

Click the link to return to the Southern Pacific Sacramento Shops Main Page

Anxious to create a rail hub and its attendant requirement for workers, in 1861 the city of Sacramento and the state of California gave the Central Pacific Railroad – progenitor of the Southern Pacific Railroad – 30 acres of swampland and a marshy lake along the Sacramento River. By 1869 the railroad had filled in 20 acres of the lake and begun construction of what became one of the most extensive railroad shop complexes in the West. Within a short time facilities included a 29-stall, 378-foot-diameter brick roundhouse; a 55-foot diameter, manually operated, iron Sellers turntable; and a 100-by-204-foot, 30-foot-high, brick erecting/machine shop. A boiler shop was built in 1872, but replaced by one 30 feet wider and 80 feet longer in 1888. A 40-foot steam powered transfer table was built to move locomotives between the machine and boiler shops. [2]

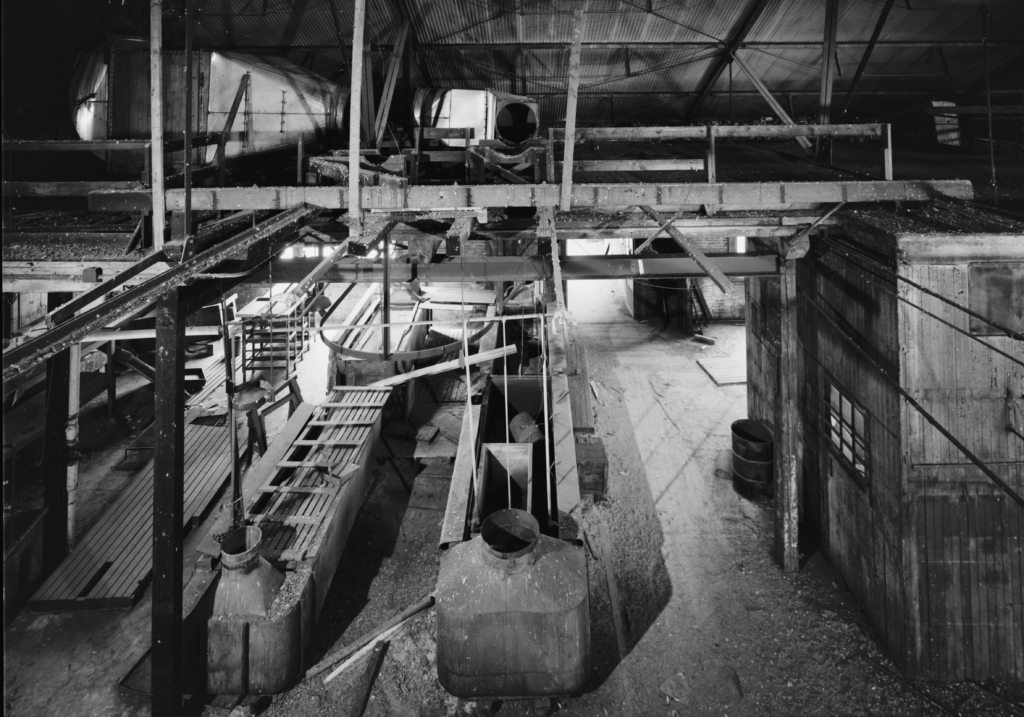

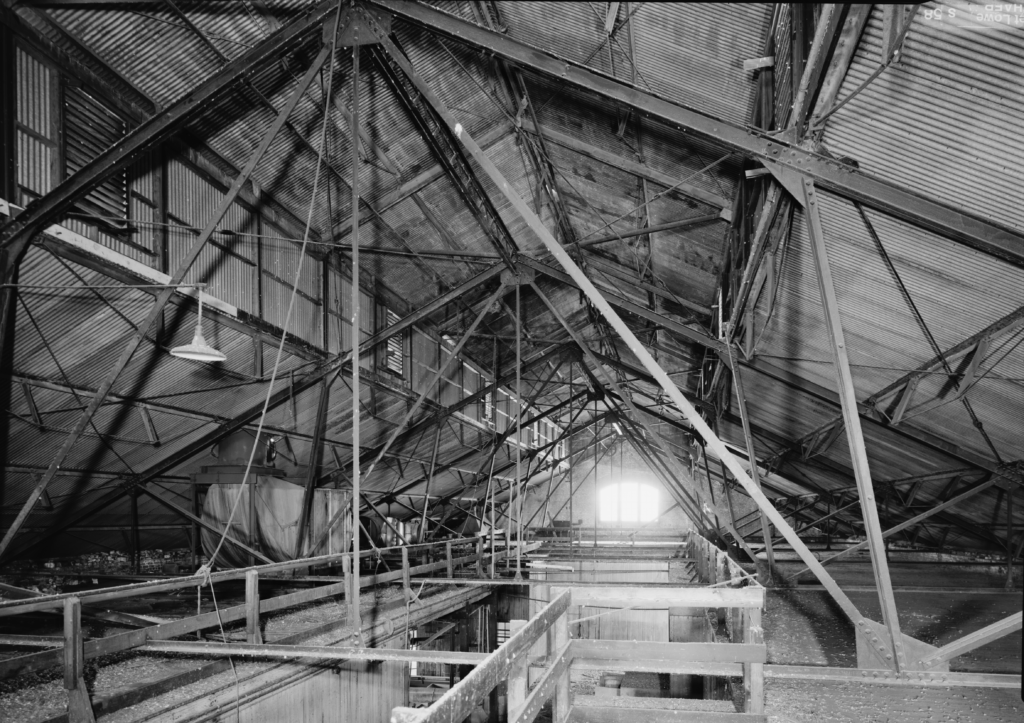

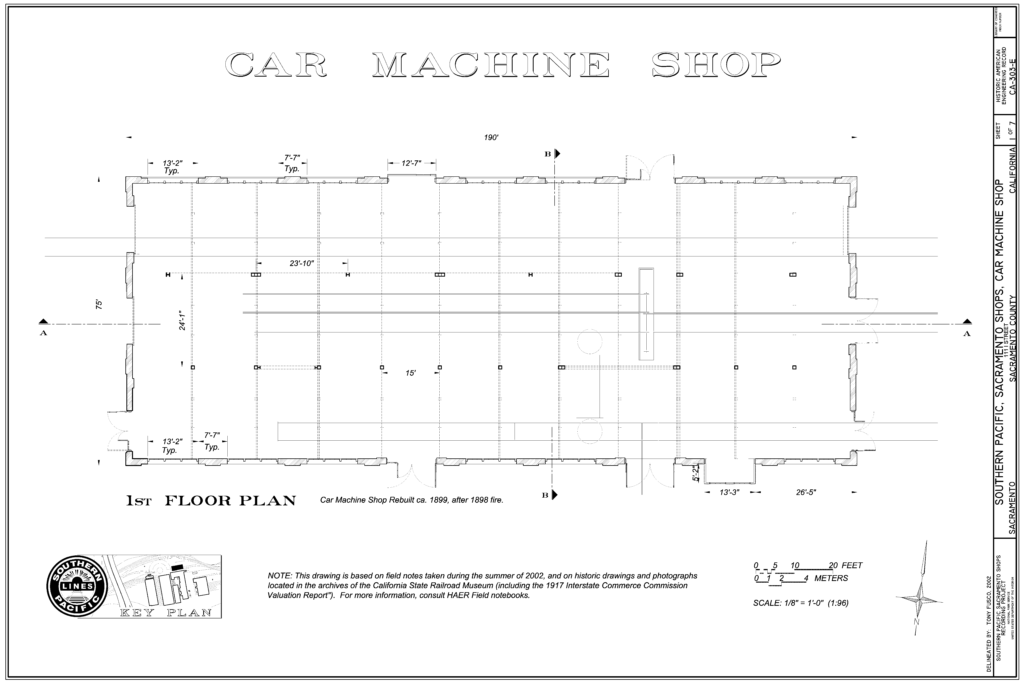

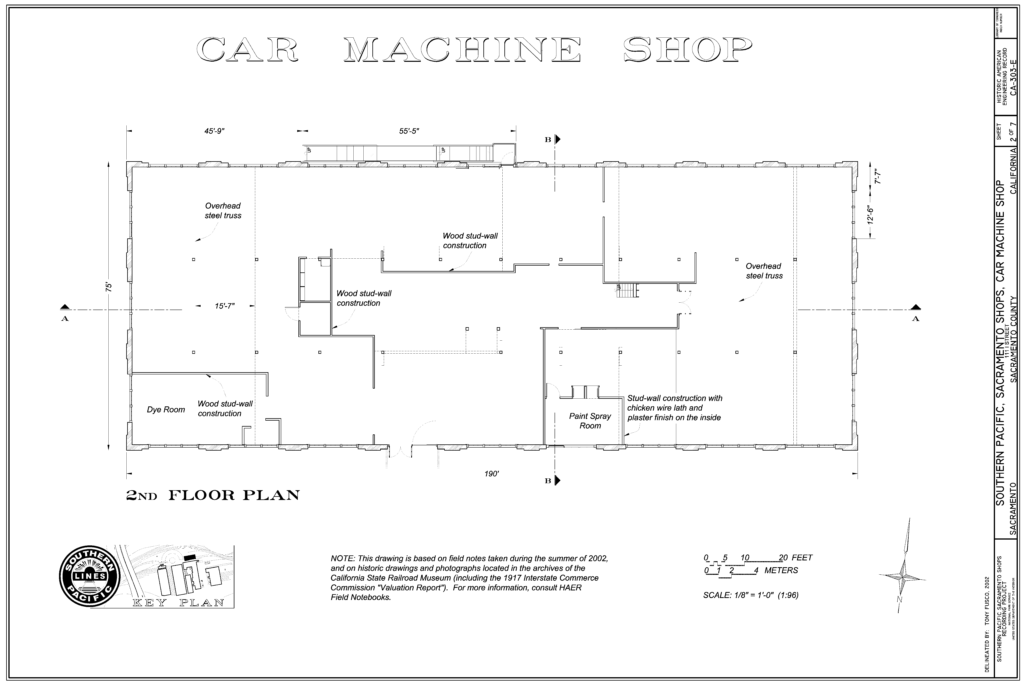

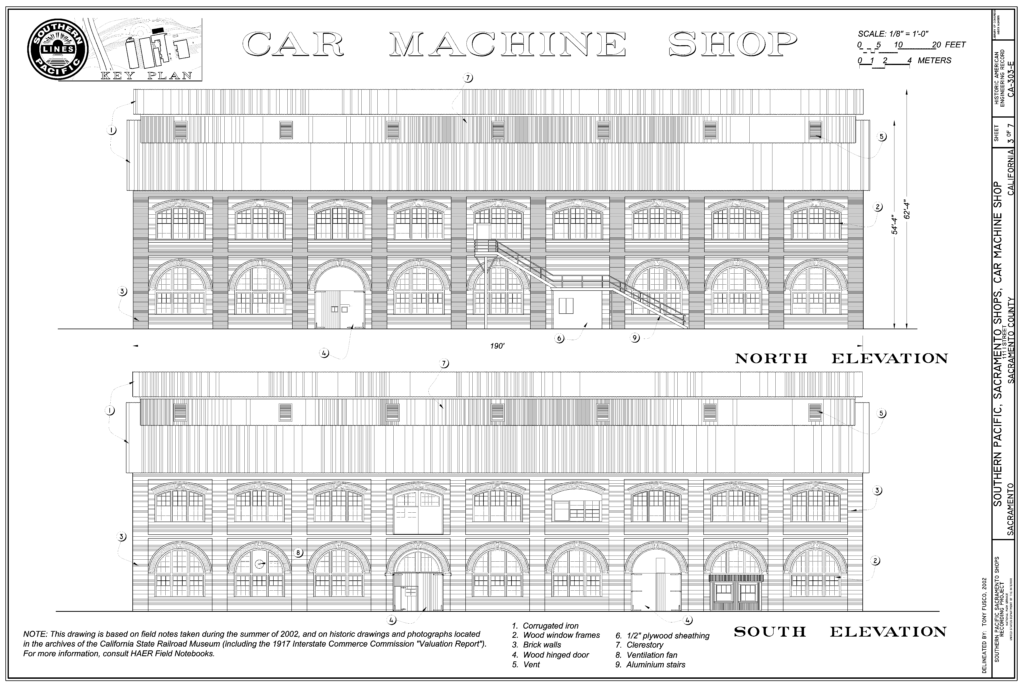

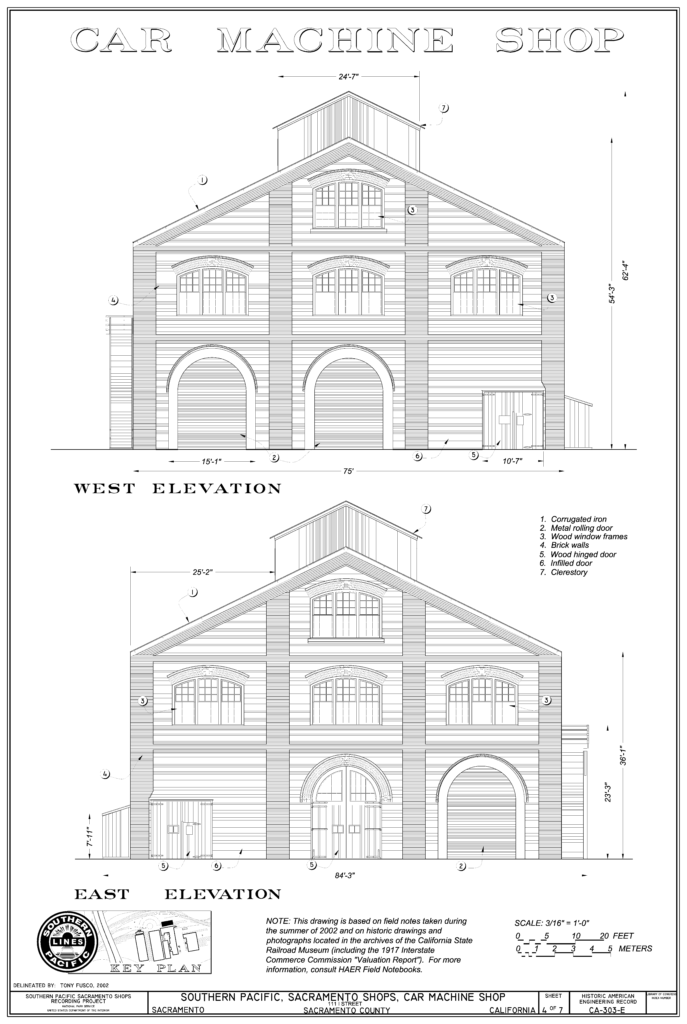

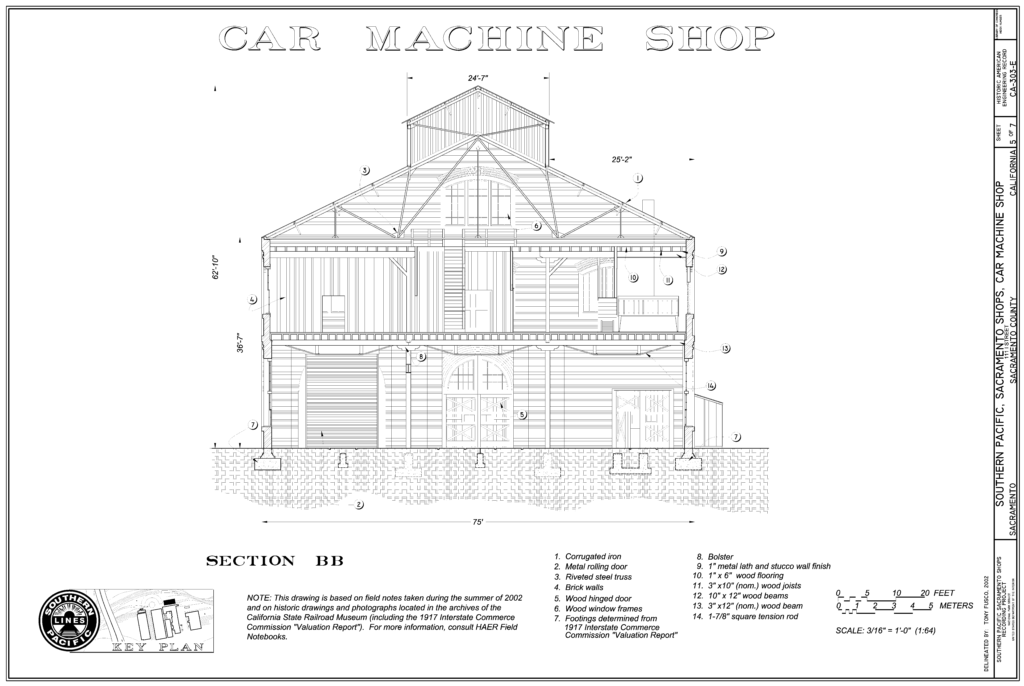

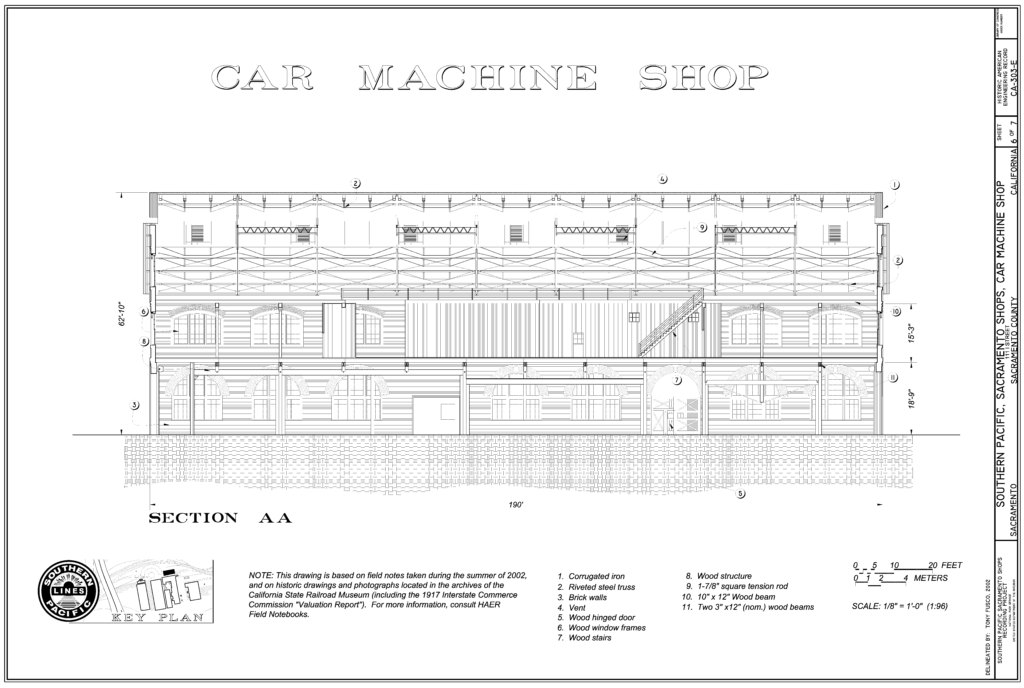

Built around 1888, the two-story car machine ship measured 75 by 190 feet. The first floor, laid out nine bays by three bays, included large doors in both ends of the building. Operations for car construction and associated machinery were housed here. The second floor hosted the plating department and upholstery shop. The plating department could coat metal trim in silver, copper, nickel and brass. The upholstery shop included rooms for dyeing, sleeping-car equipment, storage, and “hair store and picking,” where stuffing material for cushions was cleaned. [3]

After being nearly completely burned in an 1898 fire, reconstruction on the car machine ship began immediately. While the contents and wooden support structure were nearly completely destroyed, more than half of the exterior walls were salvaged as the building was rebuilt to the original plan. Although an exterior staircase had been added, no evidence of an inside stairway between the first to second floor existed at the time of the HAER survey. A bridge on the second floor of the car machine ship to the adjacent planing mill would allow use of the planing mill’s elevator and stairs to access the car machine shop second floor. [4]

By 1914 most of the first floor had been converted into a wheel shop, and by 1922 operations were limited to refurbishing passenger cars. The second floor continued to offer supporting functions: the plating department renewed all metal parts and the upholstery shop renewed old cushions, pillows, tapestry and curtains. A new vulcanizing process allowed formerly unsalvageable rubber material to be renewed as well.

The coming of diesel engines led to alterations to the building’s use and appearance. In 1945 the doors, tracks, tool shed, and office space were all repositioned to accommodate larger, faster equipment more able to handle the higher precision required in finishing diesel locomotive wheels. In the 1950s the first floor wheel shop handled engine trailing trucks and tender trucks of the remaining steam locomotives as well as diesel locomotive wheels. The southern track was also relocated four feet further south, and end doors were repositioned to meet the new track location. In 1945 the upholstery shop moved to the adjacent planing mill, permitting the 1950 move of the lacquer spray room from its seven by eight foot location to a 12 by 20 foot location. This adaptability of the building explains why it still stands where the roundhouse, its very concept outmoded by the needs of diesel engine maintenance, began to be demolished in 1959, less than a year after Southern Pacific’s last official steam run. [6]

[1] Historic American Engineering Record Survey HAER CA-303-E This project, completed in 2001-2002 was prepared by historians Carolyn Dougherty, LeeAnn Bishop Lands, J. Lawrence Lee, and Camille Vicenti. Plans were delineated by Tony Fusco and Dana Lockett. Photos were made by Jet Lowe

[2] Historic American Engineering Record Survey HAER CA-303-E Written Historical and Descriptive Data pp. 10-11 https://tile.loc.gov/storage-services/master/pnp/habshaer/ca/ca3100/ca3107/data/ca3107data.pdf accessed 06/01/2021

[3] ibid pp. 115-116

[4] ibid pp. 116-117

[5] ibid pp. 118

[6] ibid pp. 119-122, 72