Return to the Sacramento Shops main page

For the process of steam locomotive heavy repair, the boiler shop and the erecting/machine shop, were the buildings around which everything else in Southern Pacific’s Sacramento Shops revolved. The operation of a steam locomotives itself revolved around the boiler, which needed frequent maintenance, ensuring constant work for the boilermakers in the boiler shop.

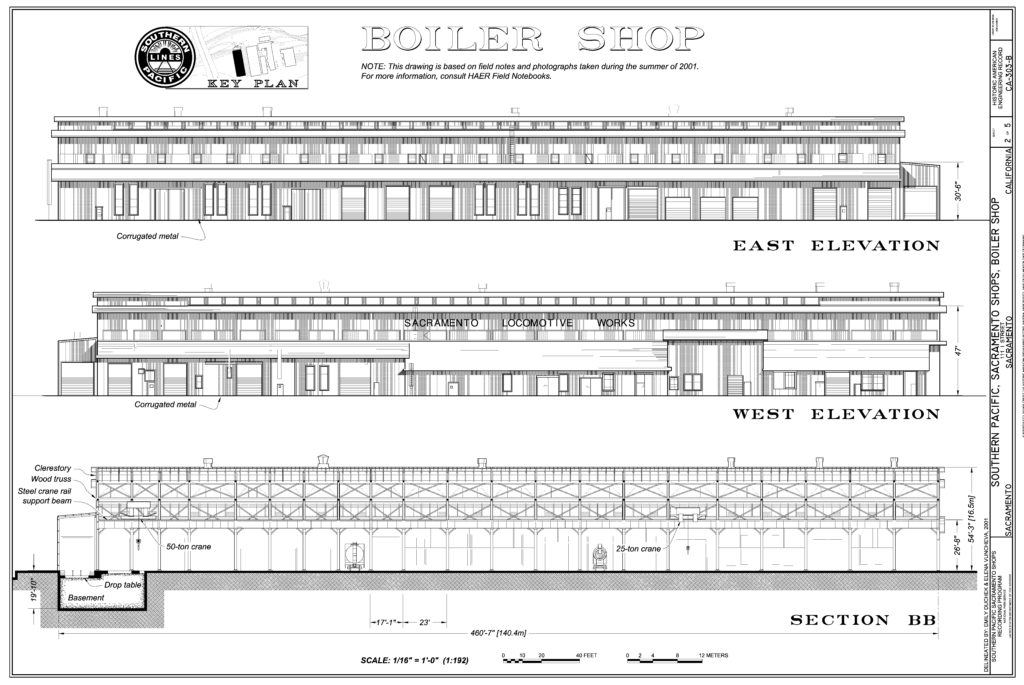

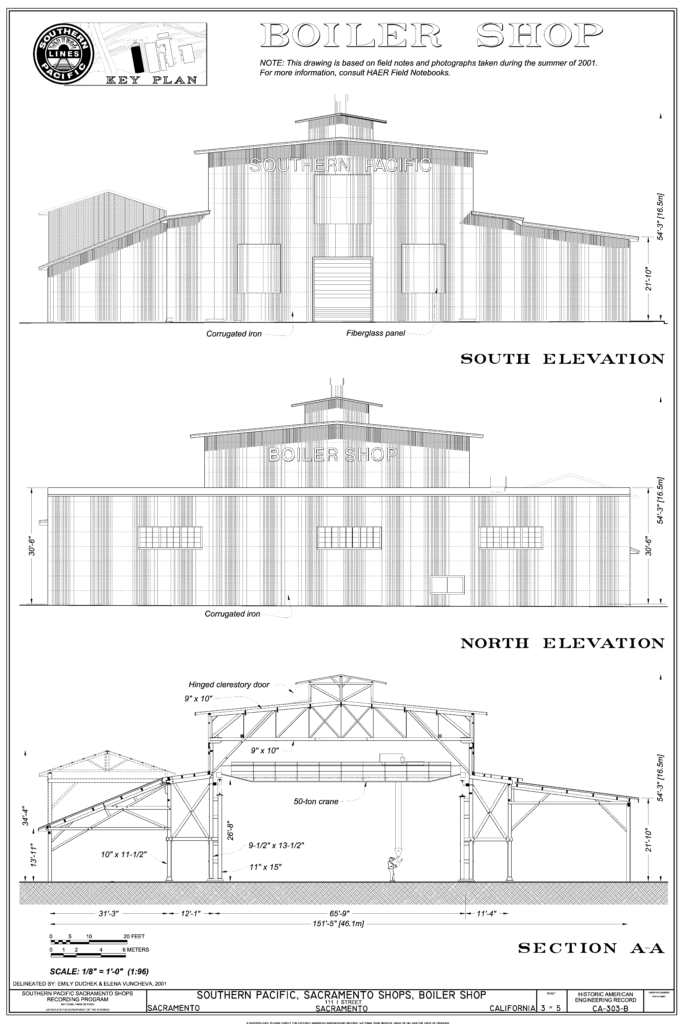

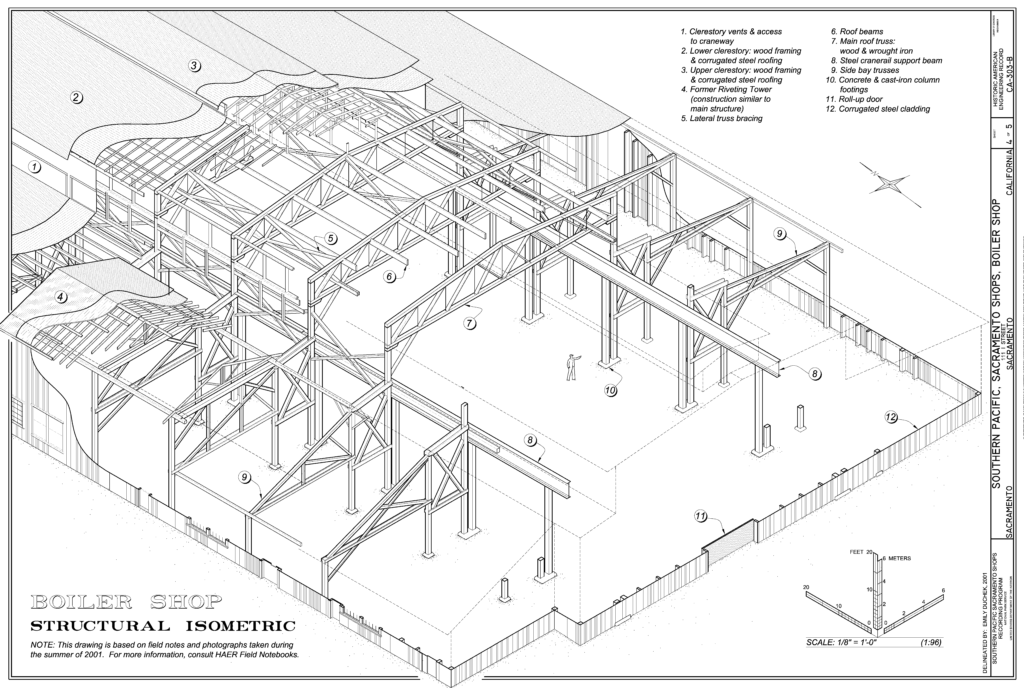

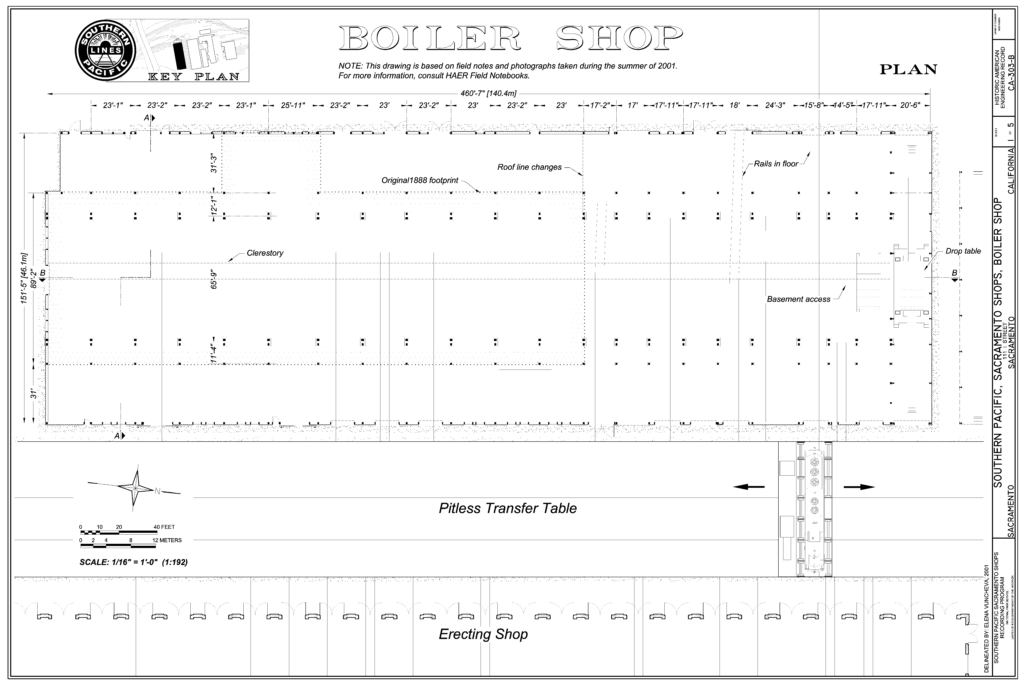

The original boiler shop, built circa 1872, was a wood an corrugated iron building 60 by 200 feet in size. In 1888, the original structure was replaced by a similar building 30 feet wider and 80 feet longer, erected further west to allow for a 40 foot steam powered transfer table that was used to shuttle locomotives to different bays of the erecting/machine shop or from there to the boiler shop.

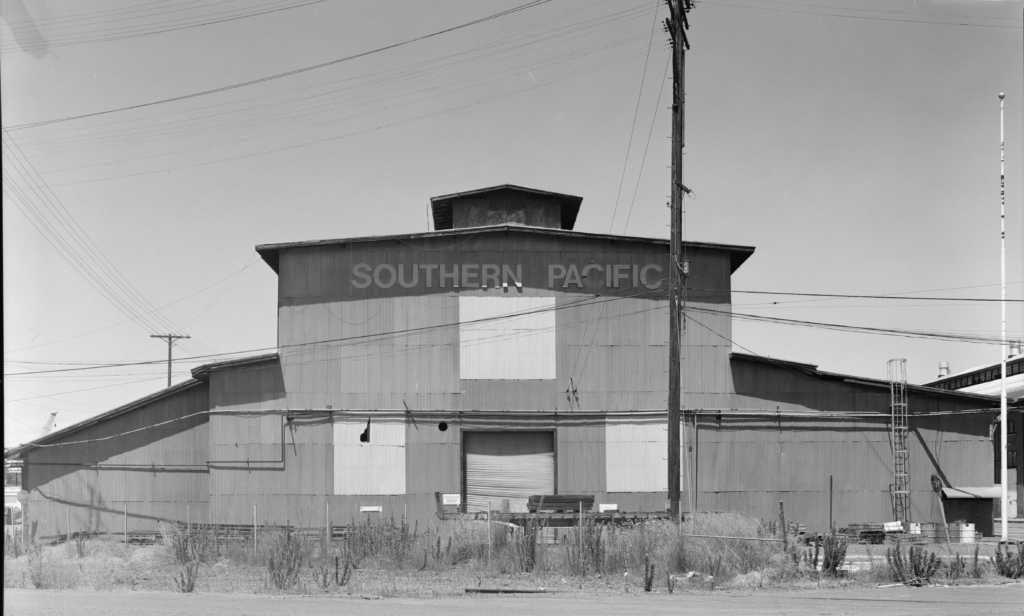

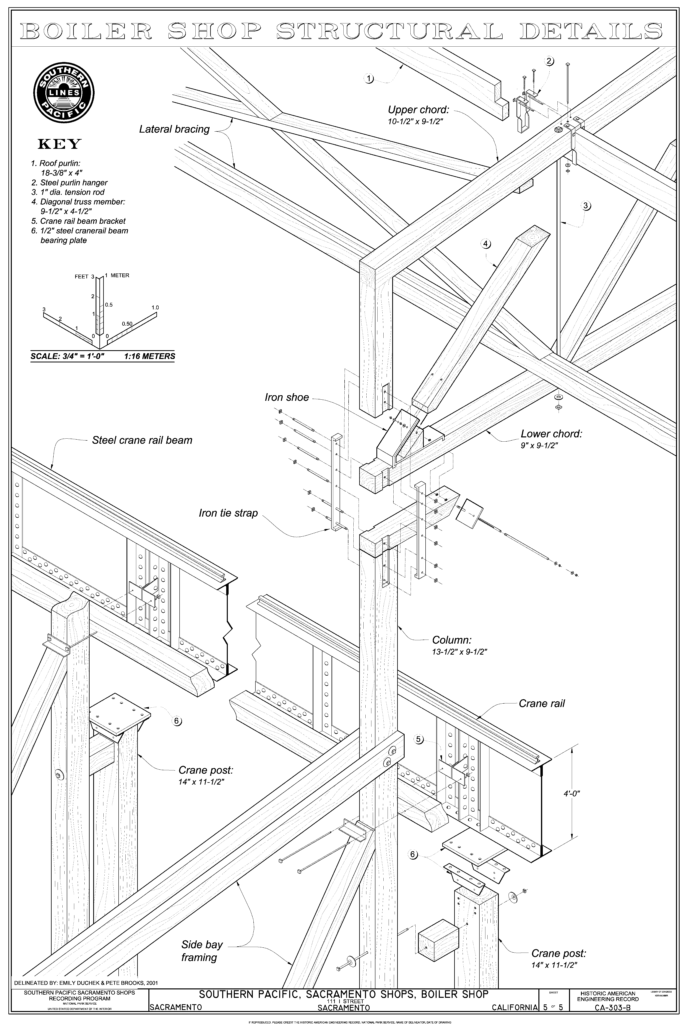

Where the erecting/machine shop and the locomotive roundhouse were masonry with “arched Italianate windows and stepped brick accents,” the wood and corrugated iron boiler shops were “devoid of embellishments.” While this construction method was less expensive than brick buildings, it also was less durable, and decay and rusting quickly took its toll.

Running maintenance, adjustments, repair of minor damage and inspections were carried out at the roundhouse, and it was only when heavy repairs, rebuilds, and modifications that would keep a locomotive out of service for days or even weeks were required that locomotives were sent to the “back shop,” the erecting/machine shop and the boiler shop and the various supporting shops that served them. [1]

Locomotives being sent to the back shop had their fires doused, their boiler drained, and their tender removed, leaving them unable to move under their own power. A small shop switcher called a “goat” was responsible for moving them to the transfer table at this point. The transfer table had a winch to pull locomotives on and off.

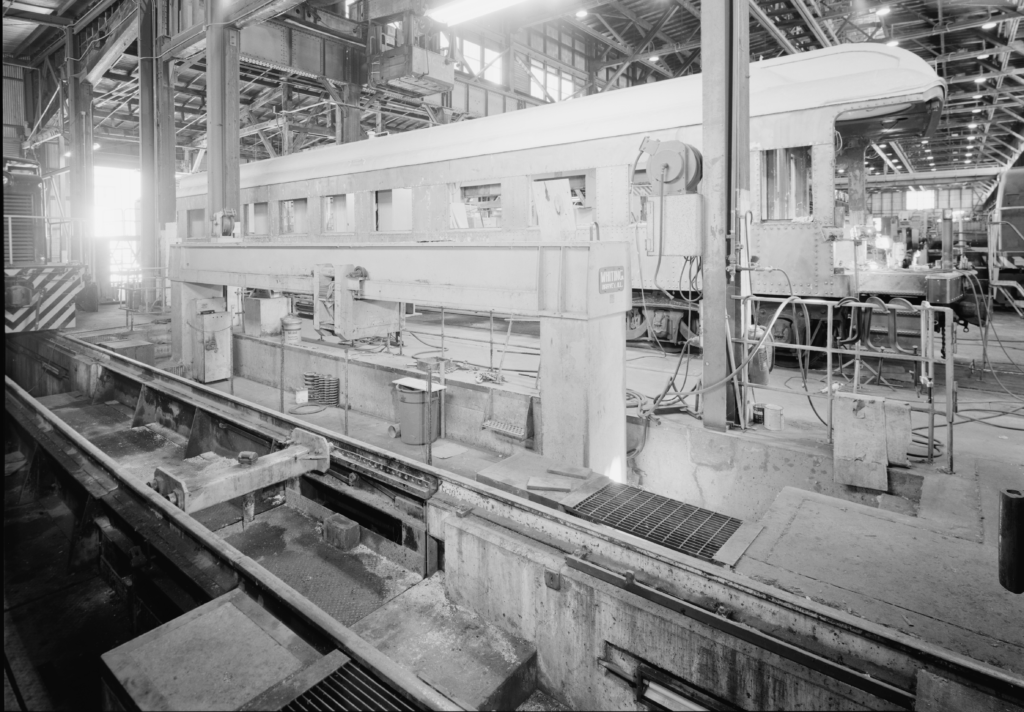

The removed tender was sent to the tank shop in the northern portion of the boiler shop. When the locomotive was disassembled in the erecting shop, if the boiler could not be repaired there, it was placed on a flat car and moved to the boiler shop via the transfer table. Otherwise, boilermakers could make repairs to it on the erecting shop floor. [2]

The boiler shop also played a part in manufacturing new locomotives from the ground up, as Sacramento Shops did on occasion when it seemed more economically feasible than buying them in the Eastern U.S. and transporting them to the West Coast, or when locomotive manufacturers’ delivery timelines were too long for pressing needs on the Southern Pacific. The decision to build ten new locomotives in 1872, as well as boilers for ferryboats, was key in the decision to build a separate boiler shop at Sacramento Shops.

The boiler shop centralized the rolls, punches, and shears that were located elsewhere. As in the other shops, the tools in the boiler shop were powered by steam-driven belts and pulleys. A hydraulic riveter was added to the west side of the building, and hydraulic cranes were used to move heavy materials until an overhead crane was added around 1917. Later air hammers were added. The boiler shop built new tanks, tenders, locomotive cabs, and smokestacks as well as repairing old ones. The boiler shop also fixed and built boilers for the company’s ferryboat fleet. [3]

By the turn of the century, like the erecting/machine shop, the boiler shop needed expansion. It was widened by 26 feet on its east and west sides, and a 20-ton electric traveling crane and new, better tools were added. In 1910 a new pit-less transfer table was installed between the boiler shop and erecting/machine shop, making it much easier for workers to move from building to building. [4]

After restrictions in acquisition eased at the end of World War I the Southern Pacific ramped up locomotive construction, and by 1920 37 locomotives were finished or under construction in the railroad’s shops. The company launched a 10 year program to expand car and locomotive building, planning to spend $12 million on rolling stock and $3 million on locomotives, with 60 percent of the cars and 70 percent of the locomotives to be manufactured in the Sacramento Shops. [5]

But technology was changing, and with it, the importance of the boiler shop. Southern Pacific began its move to diesel locomotives in 1936 with the streamlined passenger train the City of San Francisco. In 1939 the company bought 10 diesel switchers, and by 1941 had plans to purchase 40 more.

World War II forced the railroad to postpone its purchase of road freight diesel engines, but that only postponed the inevitable. In 1945 the railroad announced plans to add a pair of streamlined diesel-powered Shasta Daylight trains to the San Francisco-Portland route. In 1946 they ordered five 6,000 horsepower passenger diesel locomotives and 20 similar freight locomotives. By the 1950s the company had committed itself to full transition to diesel. And diesel engines did not have a need for boilers – or boilermakers.

But the switch to diesels was not immediate, but instead a transition that required repair shops to service both steam and diesel locomotives. The shops gradually reserved more and more space for diesel repairs, and began altering or removing steam-centered repair stations.

The first steam facilities the SP changed were running repair and turning facilities. Multiple unit lash-ups of diesel locomotives were too long for steam locomotive roundhouses, so those were some of the first buildings to be eliminated in favor of long rectangular structures. These lash-ups also had a cab at each end, so there was no need to turn them like steam locomotives, so turntables were of little use.

And the boiler shop? It became the truck shop, responsible for rebuilding the wheel sets removed from diesel locomotives in the erecting shop. Former Boiler Shop is presently used as California State Railroad Museum’s Restoration Shop. [6]

This recording project was completed by the Historic American Engineering Record; the Erecting and Machine Shop Survey HAER CA-303-A. This project, completed in 2001-2002 was prepared by historians Carolyn Dougherty, LeeAnn Bishop Lands, J. Lawrence Lee, and Camille Vicenti. Plans were delineated by Joshua May, Pete Brooks, Theresa English, Elena Vuncheva, and Emily Duchek. Photos were made by Jet Lowe.

[1] Historic American Engineering Record Survey HAER CA-303 Written Historical and Descriptive Data https://tile.loc.gov/storage-services/master/pnp/habshaer/ca/ca3100/ca3107/data/ca3107data.pdf accessed 06/01/2021 pp 11-15

[2] ibid pp18-22

[3] ibid pp 31-39

[4] ibid pp 42-44

[5] ibid pp 46-47

[6] ibid pp 57-75