Return to the Sacramento Shops main page

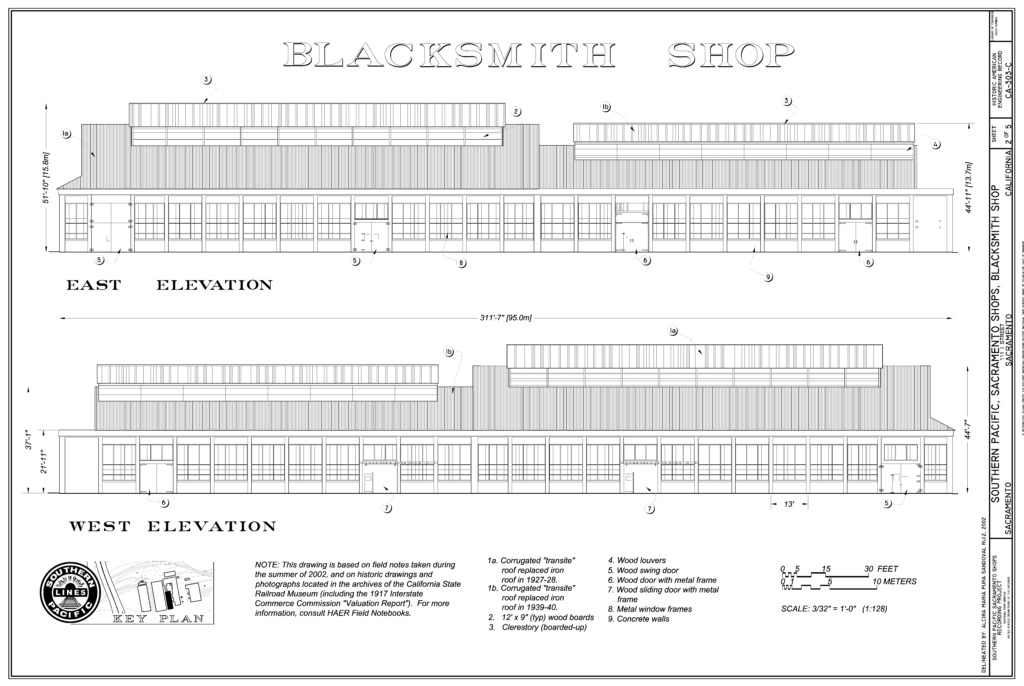

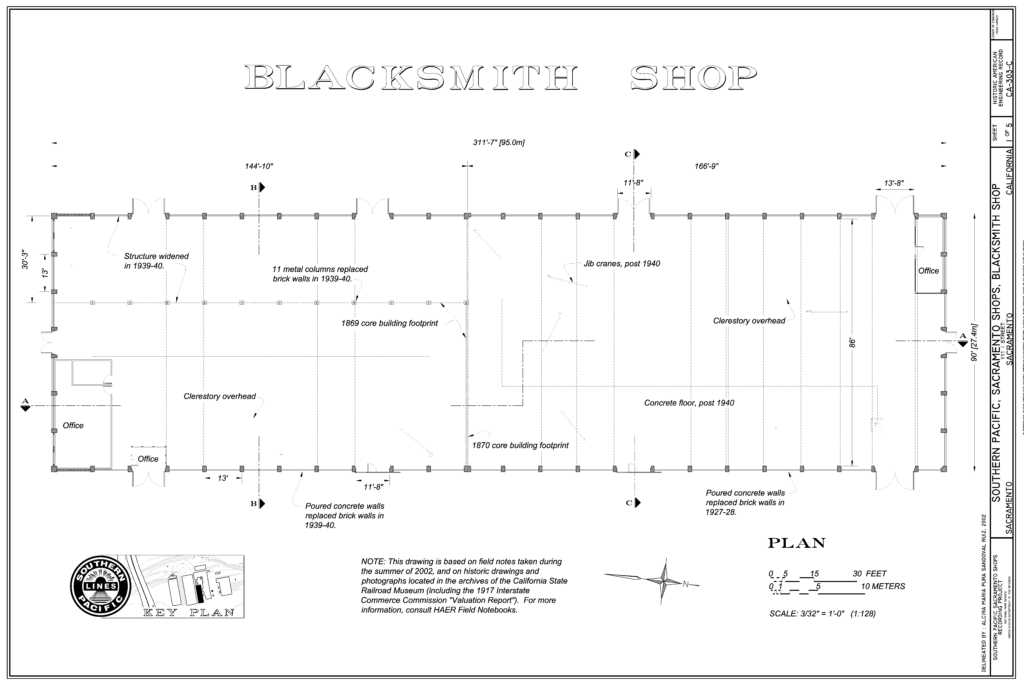

Originally built in 1869, the blacksmith shop at Southern Pacific’s Sacramento Shops was 60 by 150 feet in size. It was placed east of the machine shop. Power was passed from the machine shop to the blacksmith shop by a flat belt from the machine shop’s line shaft, which was connected to the powerhouse engine by another belt. The blacksmith shop’s line shaft was oriented north-south, and belts from this line shaft powered the blacksmith shop’s machinery. [1]

Constructed mostly of brick, with pilasters and rounded arch windows, the south end of the boiler shop was a temporary wood wall to facilitate later expansion. This echoed the design philosophy of other structures at Sacramento Shops. The roof was wooden trusses supporting corrugated iron panels.

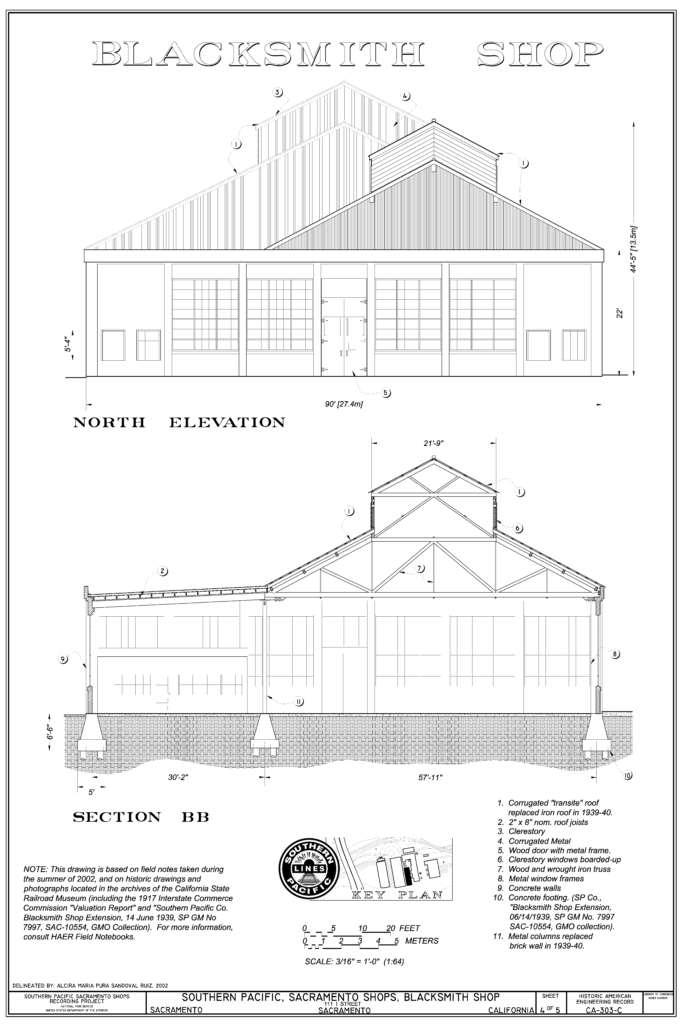

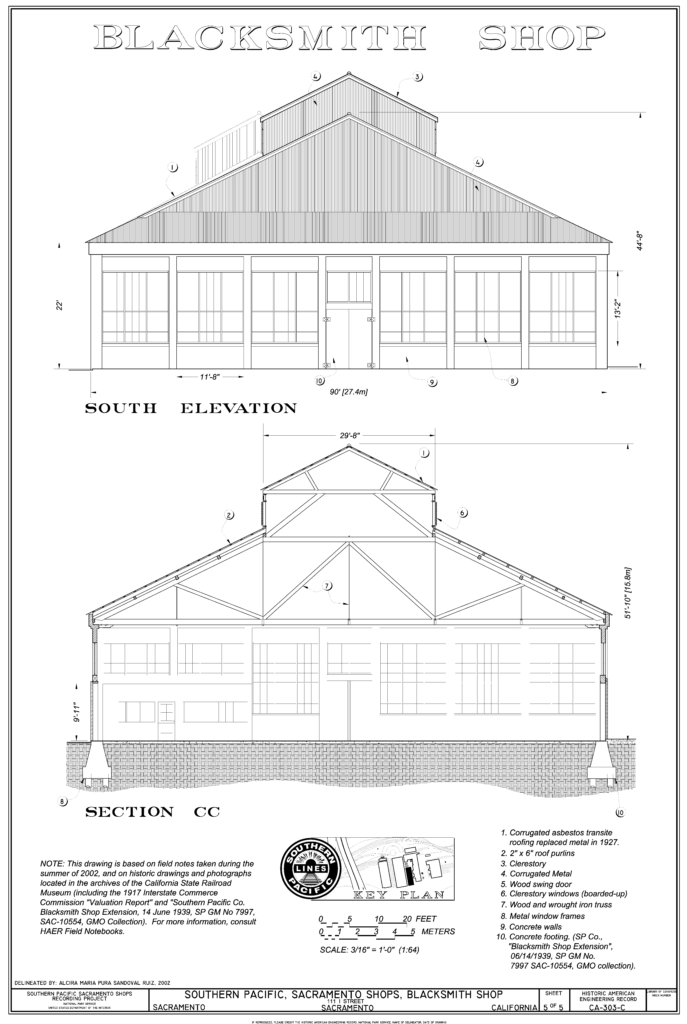

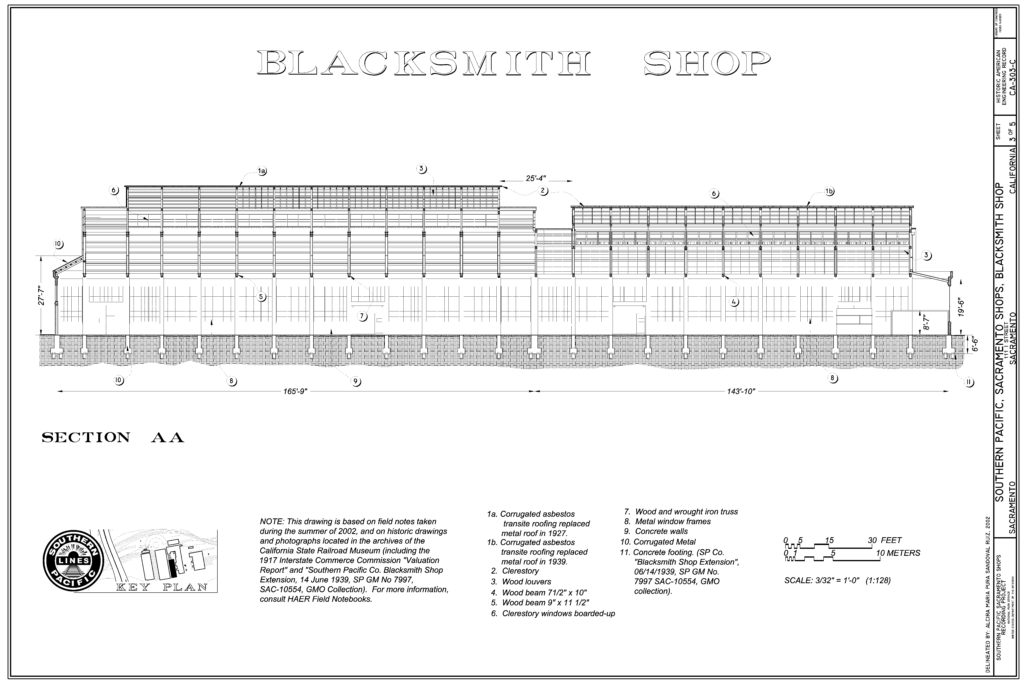

Within a year, the blacksmith shop was enlarged by adding a 167 by 90 foot addition, again constructed of brick, other than the southern wall, which followed the previous construction of wood in case further addition was required. The roof of the addition was built in the same way as the original.

Hosting all of the shop’s iron forging operations, dissipating heat would be an issue. Toward this end, the walls were 22 feet high, lifting the roof and monitor to allow heat and fumes to rise and exit the building. Horizontal sashes lined both sides of the roof monitors to create the airflow needed to remove the heat and smoke generated by iron forging that was not captured by the hoods and exhaust stacks lining the length of each wall where the forges were located. The side windows opened at top and bottom to allow fresh air in to replace the air that exited the roof monitors and smoke stacks as well as provide natural light inside the building.

By 1880, there were 50 forges, two furnaces, and a trip hammer and other metal-shaping machinery in operation in the blacksmith shop. By 1894 the shop was divided into two departments. The northern half of the building housed the department responsible for “all wrought iron for new cars and locomotives,” the southern half was the recycling plant that worked scrap iron into slabs for reuse. There was a single track in the southern portion of the building for unloading scrap iron and loading of heavy items forged there.

The office took up a 12 by 15 foot corner of the building, with a second floor added after 1888. This remained until 1939.

By 1915, the heat and harsh atmosphere from smithing operations had seriously deteriorated the walls of the northern section of the blacksmith shop, and in 1917 the walls were torn down and replaced by new brick walls with wider windows with concrete lintels that allowed the rectangular windows to stand nearly the full height of the walls. In 1927, renovations of the southern end of the building introduced reinforced concrete curtain wall construction, which allowed very large windows, creating a “modern well-lighted shop,” as reported in an SP Bulletin. This renovation stands out, as the frugal railroad had rebuilt some of the other original buildings, but only after they were destroyed by fire.

The railroad kept operations running in the north side of the building while the southern half was rebuilt. Temporary supports were built for the roof trusses, and after demolishing the old wall, the new concrete walls were cast in their place. The roof was then lowered back into place and windows installed. The same renovation was planned for the northern half of the building, but the Great Depression put off that work for 11 years after the completion of the southern wall, and it was finally started in 1939.

When the concrete was poured for the walls of the north end of the building, it was expanded to the 90 foot width of the southern addition. The original 60 foot wood truss roof was maintained by building a line of steel columns where the old east wall had been, and a new, nearly flat roof covered the added 30 feet of width.

Aside from this discrepancy, it would be hard to tell that there was a decade between the rebuilding of the southern and northern halves of the blacksmith shop. A telltale sign of the changing times between the two projects can be noticed in the doors. Those on the south end of the building are wood, with square hinges bolted into the concrete walls. The doors on the northern half are covered with galvanized sheet metal with hinges connecting to steel bars set into the concrete pilasters.

While the old roof was reused to cut the costs of the blacksmith shop rebuilding, but by the time the 1939 project was completed, plans were begun to replace the more than 40 year old leaky, rusted iron roofing with corrugated transite which was already in use on the southern half of the building. That material was still present on the building at the time of the HAER/HABS survey in 2001.

Like the rest of the shops, dieselization changed the nature of the work done in the blacksmith shop. From the 1930s to 1960s the welding shop continued to use the northernmost five bays, and a new rod shop was located in the remainder of the northern bays. Blacksmithing operations continued, but by the 1960s a locomotive machine shop joined the welding and rod operations in the building.

This recording project was completed by the Historic American Engineering Record; the Erecting and Machine Shop Survey HAER CA-303-C. This project, completed in 2001-2002 was prepared by historians Carolyn Dougherty, LeeAnn Bishop Lands, J. Lawrence Lee, and Camille Vicenti. Plans were delineated by Alicira Maria Pura Sandoval Ruiz, Joshua May, Pete Brooks, Theresa English, and Elena Vuncheva. Photos were made by Jet Lowe.

[1] Historic American Engineering Record Survey HAER CA-303 Written Historical and Descriptive Data pp. 95-105 https://tile.loc.gov/storage-services/master/pnp/habshaer/ca/ca3100/ca3107/data/ca3107data.pdf accessed 06/01/2021